Stainless hlau gasket xov zoo Hoobkas ncaj muag

Lub cev muaj zog

1. Muaj chloride ions nyob rau hauv qhov chaw ua haujlwm.

chloride ions muaj nyob rau hauv ntsev, hws, dej hiav txwv, cua, av, thiab lwm yam. Stainless hlau corrodes sai nyob rau hauv lub xub ntiag ntawm chloride ions dua li cov hlau me me.

Yog li kev siv stainless hlau ib puag ncig muaj qhov yuav tsum tau ua, thiab yuav tsum tau so ntau zaus, tshem cov plua plav, ua kom huv thiab qhuav.(Qhov no muab nws "kev siv tsis tsim nyog.")

Muaj ib qho piv txwv hauv Tebchaws Meskas: ib lub lag luam tau siv lub thawv ntoo qhib los tuav cov tshuaj uas muaj chloride ions.Lub thawv tau siv ntau tshaj li ib puas xyoo thiab tau npaj yuav hloov rau xyoo 1990.Vim tias cov khoom siv ntoo qhib tsis niaj hnub txaus, lub thawv tau corroded thiab leaked 16 hnub tom qab hloov nrog stainless hlau.

2. Tsis muaj tshuaj kho.

Cov ntsiab lus alloy tsis yaj rau hauv matrix, ua rau cov ntsiab lus tsis tshua muaj hlau nyob hauv cov qauv matrix thiab tsis zoo corrosion kuj.

3. Cov ntaub ntawv zoo li no tsis muaj titanium thiab niobium muaj lub ntuj nyiam rau intergranular corrosion.

Qhov sib ntxiv ntawm titanium thiab niobium, ua ke nrog kev kho mob ruaj khov, tuaj yeem txo qhov kev sib txhuam ntawm intergranular.

Nyob rau hauv cov huab cua los yog tshuaj corrosion nruab nrab tuaj yeem tiv taus corrosion ntawm cov hlau alloy siab, stainless hlau yog qhov zoo nkauj thiab zoo corrosion tsis kam, tsis tas yuav tsum tau plated thiab lwm yam kev kho deg, thiab ua si lub hauv paus nto ntawm stainless hlau, siv nyob rau hauv ntau yam ntawm ib hom hlau, feem ntau hu ua stainless hlau.Sawv cev ntawm kev ua tau zoo ntawm 13 chromium steel, 18-8 chromium nickel steel thiab lwm yam hlau alloy siab.

Los ntawm metallographic taw tes ntawm view, vim hais tias stainless hlau muaj chromium thiab nto ntawm tsim ntawm ib tug nyias chromium zaj duab xis, cov zaj duab xis sib cais los ntawm cov pa oxygen nyob rau hauv cov hlau ntxeem tau ntawm corrosion kuj.

Yuav kom tswj tau qhov corrosion kuj muaj nyob rau hauv stainless hlau, hlau yuav tsum muaj ntau tshaj 12% chromium.

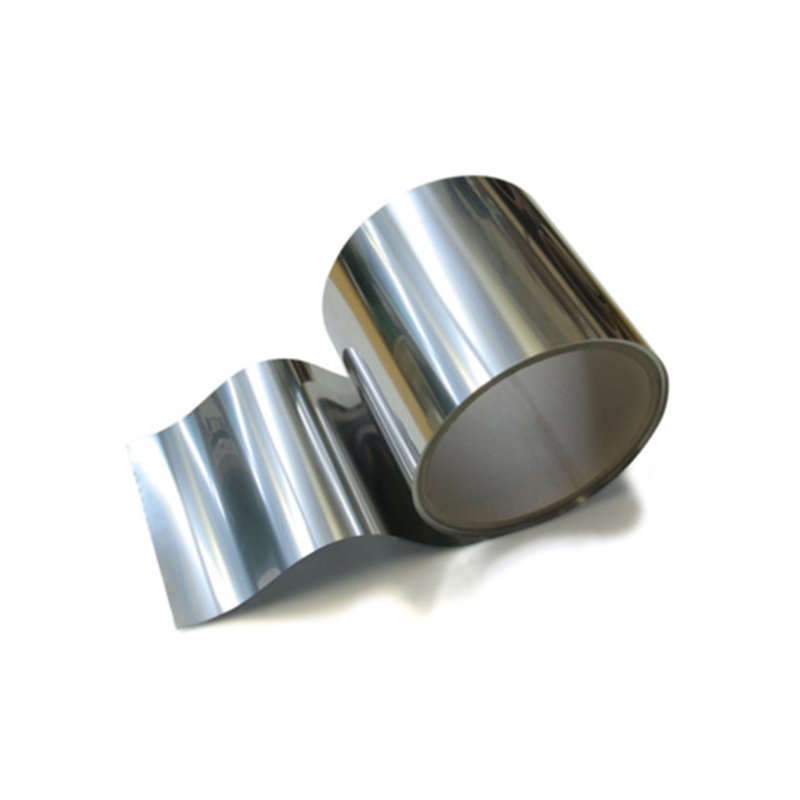

304stainless hlau Shim Phaj yog universal stainless hlau, uas yog dav siv nyob rau hauv kev tsim cov khoom thiab cov khoom uas yuav tsum tau muaj zoo meej khoom (corrosion kuj thiab formability).

304 stainless hlau yog ib hom ntawm stainless hlau ua raws li ASTM cov qauv hauv Tebchaws Meskas.304 yog sib npaug rau Tuam Tshoj 0Cr19Ni9 (0Cr18Ni9) stainless hlau.304 muaj 19% chromium thiab 9% npib tsib xee.

304 yog feem ntau siv stainless / kub resistant steel.Siv rau hauv cov khoom siv khoom noj khoom haus / xiton chemical khoom / nuclear zog, thiab lwm yam.

304 sib raug rau Suav hom 0Cr18Ni9,1Cr18Ni9Ti, carbon ntsiab lus ≤0:08%

304Lstainless hlau Shim Phaj yog ib qho txawv ntawm 304stainless hlau Shim Phaj stainless hlau nrog qis carbon cov ntsiab lus thiab yog siv rau vuam daim ntaub ntawv.Cov ntsiab lus qis dua txo qis carbides nag lossis daus nyob rau hauv thaj chaw uas muaj kev kub ntxhov nyob ze ntawm qhov vuam, uas tuaj yeem ua rau muaj kev cuam tshuam ntawm intergranular corrosion (welding yaig) hauv stainless hlau hauv qee qhov chaw.

Tsis muaj

| T | tawv | tawv | Precipitation hardening tshav kub kho lub xeev | conductive% | ||||||

| tawv | tawv | Lub zog tawm los N / mm | Tensile zog N / mm | elongation% | Kev kho cua sov | hardness HV | Lub zog tawm los N / mm | Tensile zog N / mm | ||

| 301- PAB | 1/2 H | 340 ± 30 | ≥510 | ≥930 | ≥10 | - | - | - | - | 2.3 |

| 3/4 H | 400 ± 30 | ≥745 | ≥1130 | ≥5 | - | - | - | - | 2.3 | |

| H | 460 ± 30 | ≥1030 | ≥1320 | - | - | - | - | - | 2.3 | |

| EH | 510 ± 20 | ≥1275 | ≥1570 | - | - | - | - | - | 2.3 | |

| SEH | ≥530 | ≥1450 | ≥1740 | - | - | - | - | - | 2.3 | |

| 304- PAB | 1/2 H | 280 ± 30 | ≥470 | ≥780 | ≥6 | - | - | - | - | 2.3 |

| 3/4 H | 340 ± 30 | ≥665 | ≥930 | ≥3 | - | - | - | - | 2.3 | |

| H | ≥370 | ≥880 | ≥1130 | - | - | - | - | - | 2.3 | |

| 631- ZPO | 0 | ≤200 | - | ≤1030 | ≥ 20 | TH1050RH950 | ≥345≥392 | ≥960≥1030 | ≥1140≥1230 | 2.3 |

| 1/2 H | 375 ± 25 | - | ≥1080 | ≥5 | CH | ≥380 | ≥880 | ≥1230 | 2.3 | |

| 3/4 H | 425 ± 25 | - | ≥1180 | CH | ≥450 | ≥1080 | ≥1420 | 2.3 | ||

| H | ≥450 | - | ≥1420 | CH | ≥530 | ≥1320 | ≥1720 | 2.3 | ||